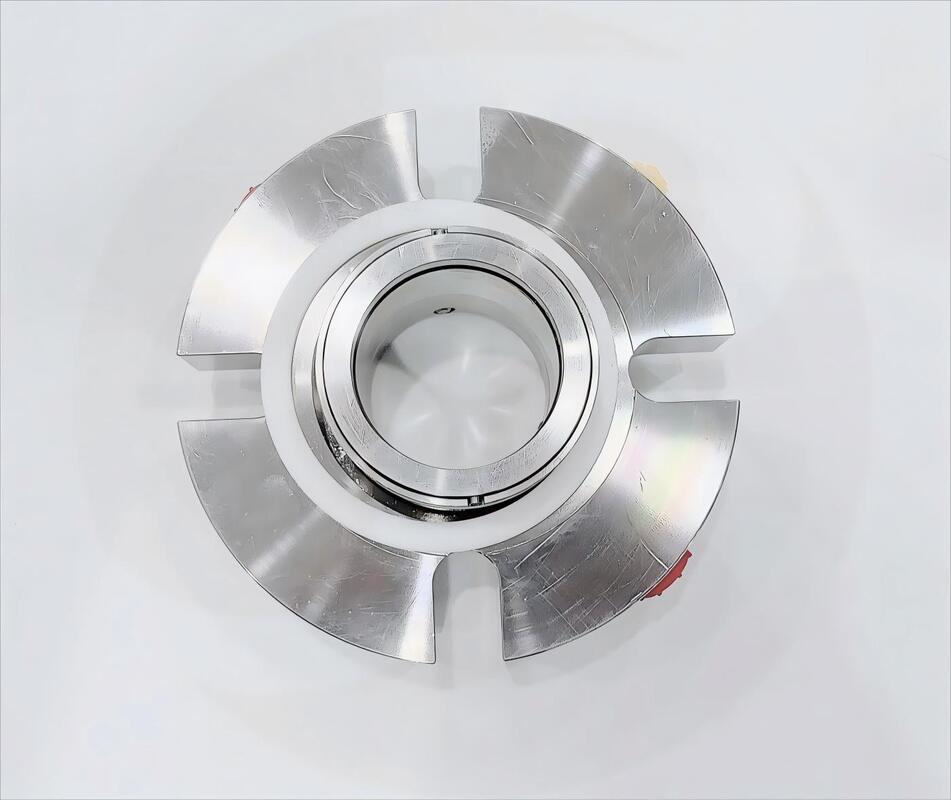

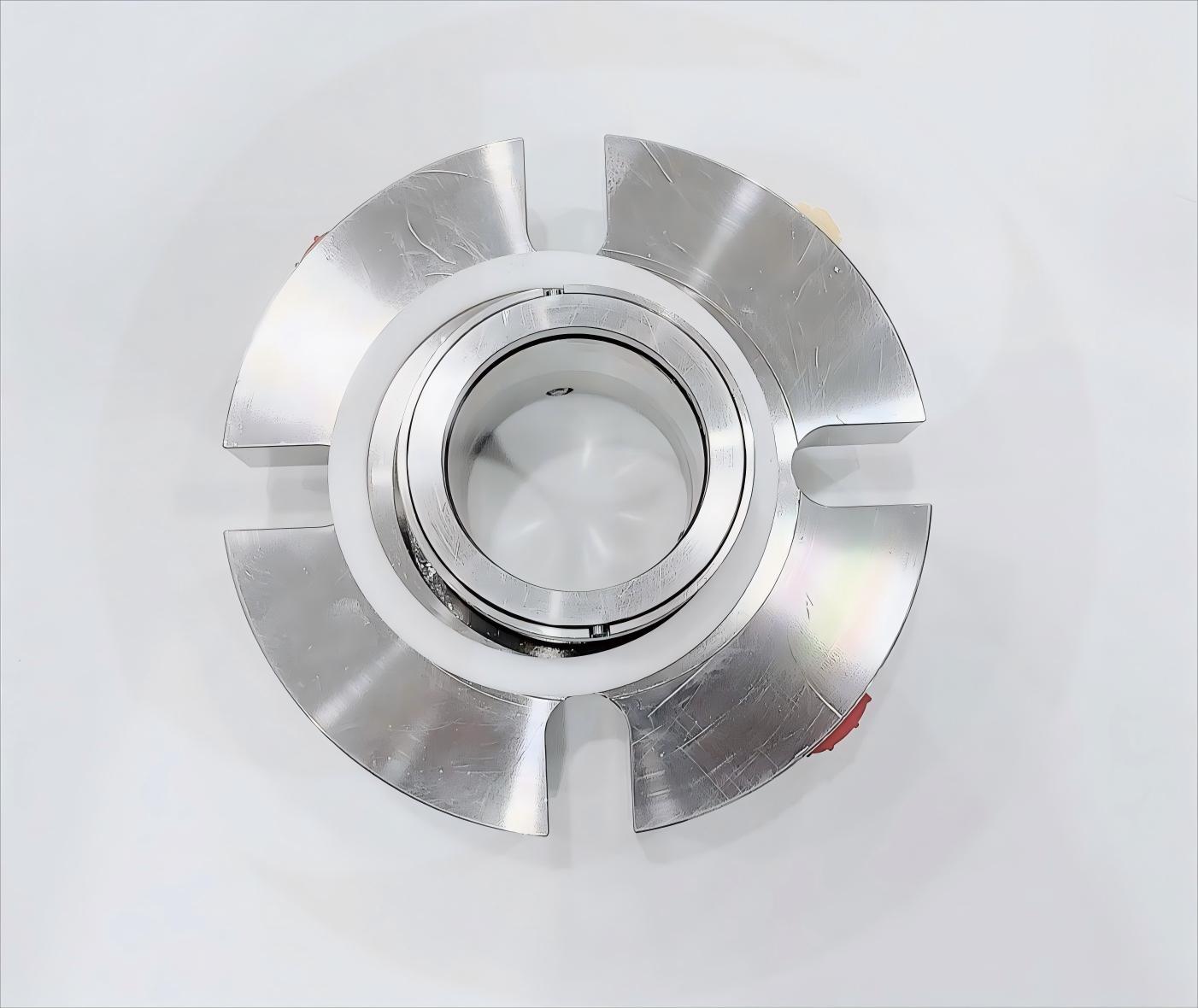

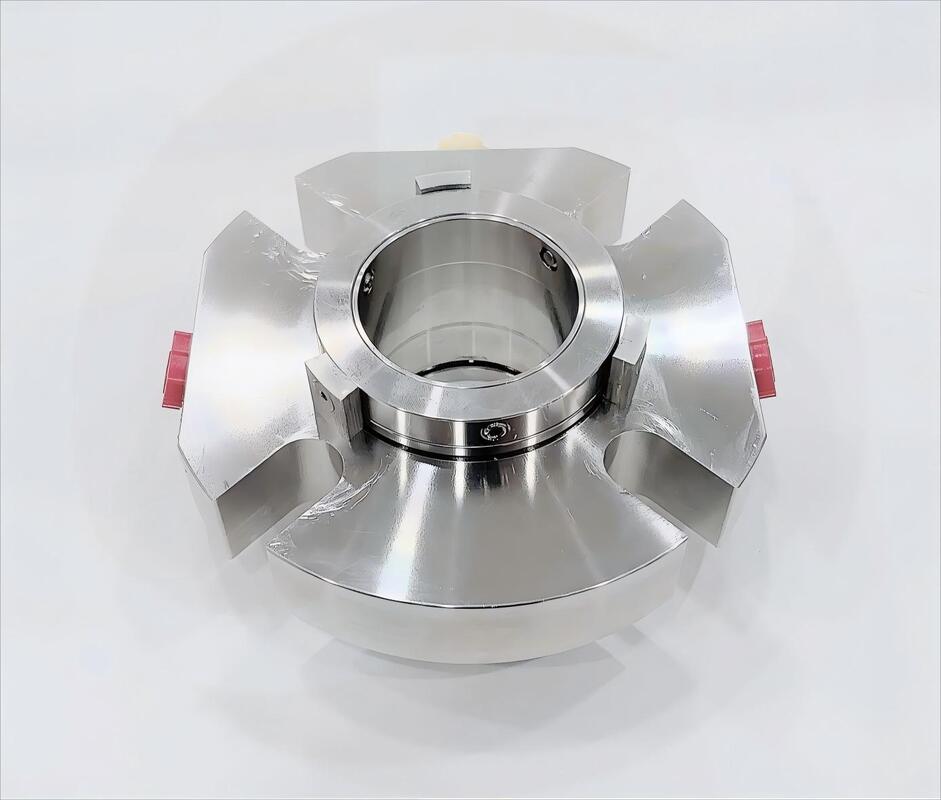

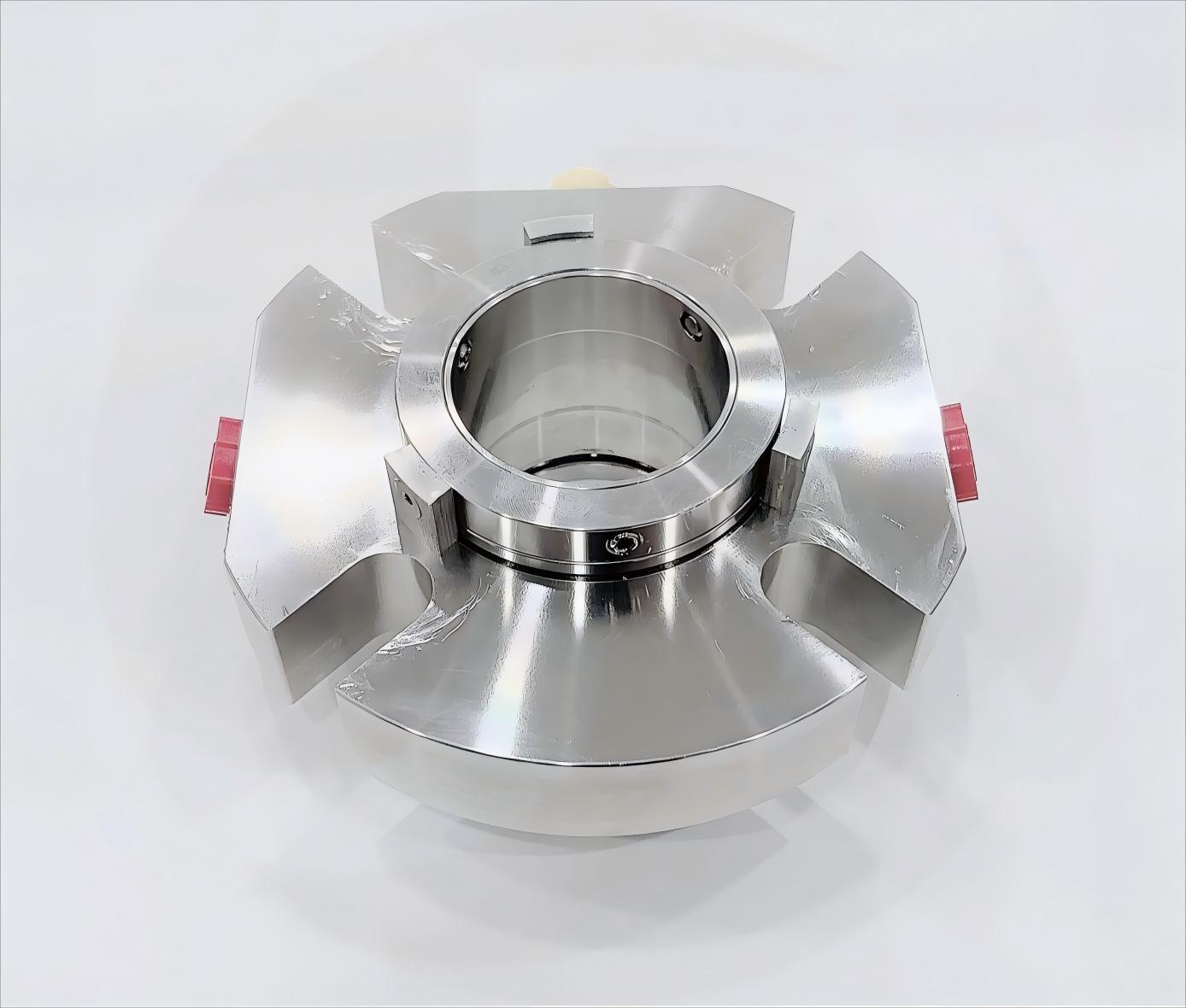

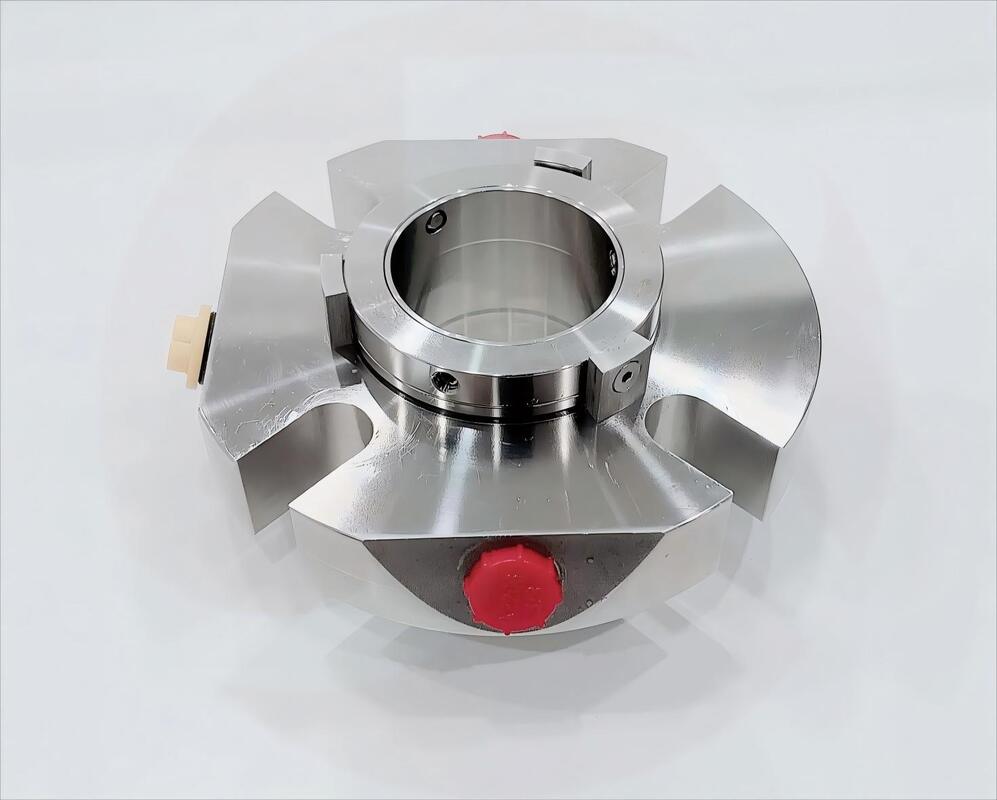

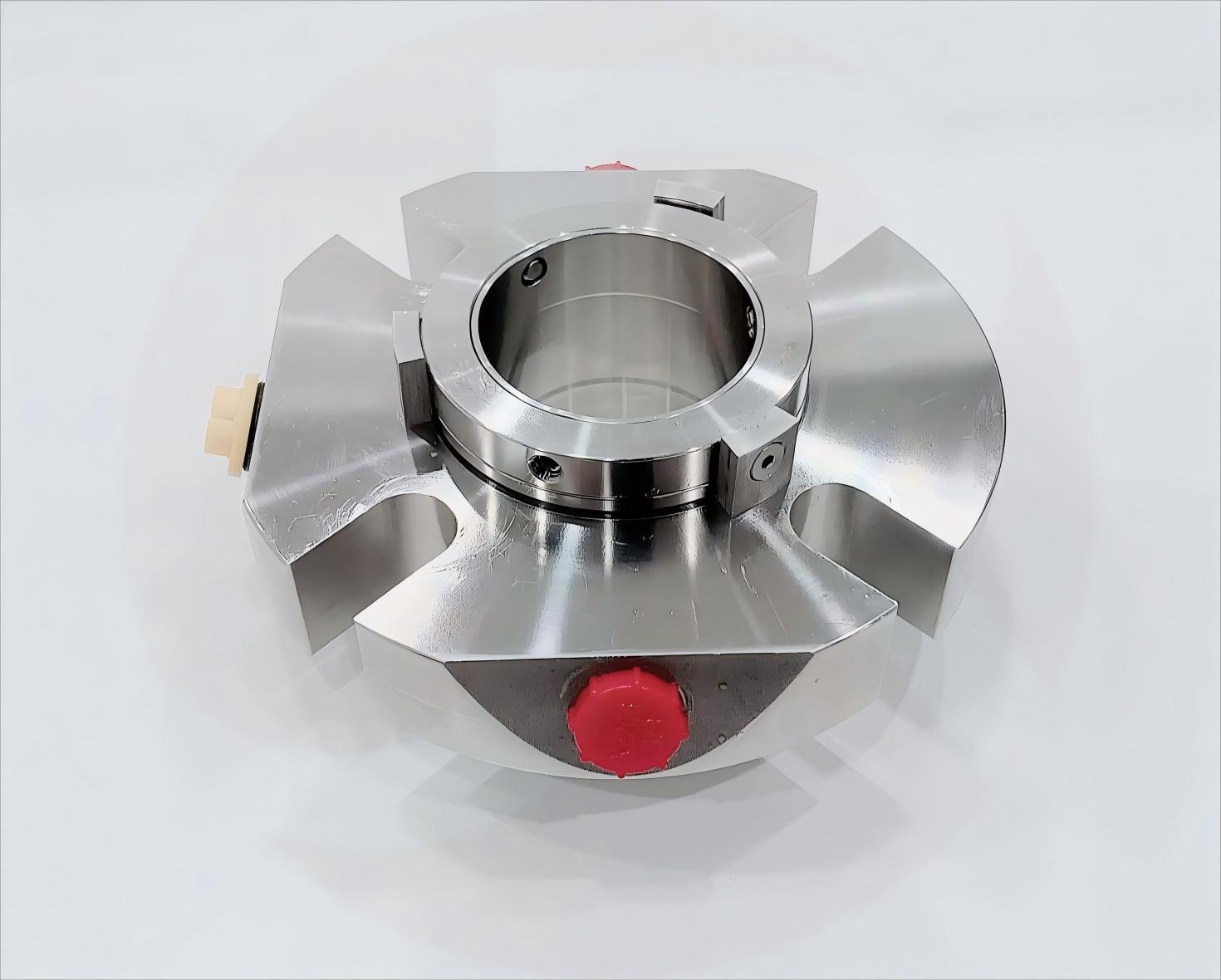

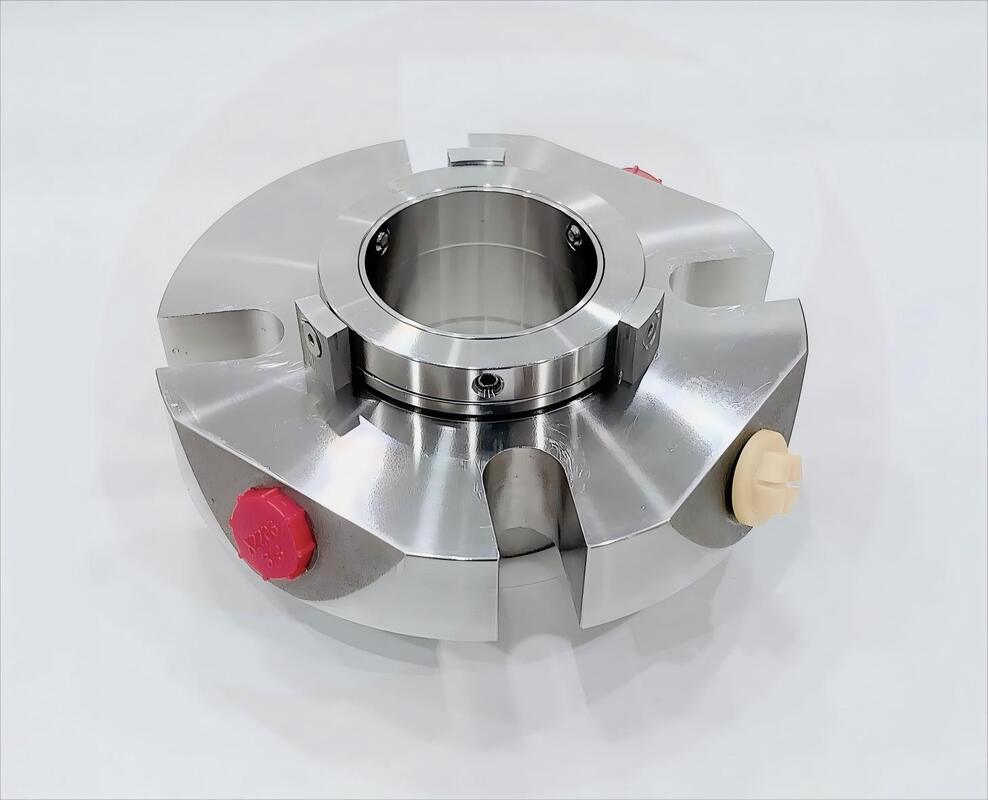

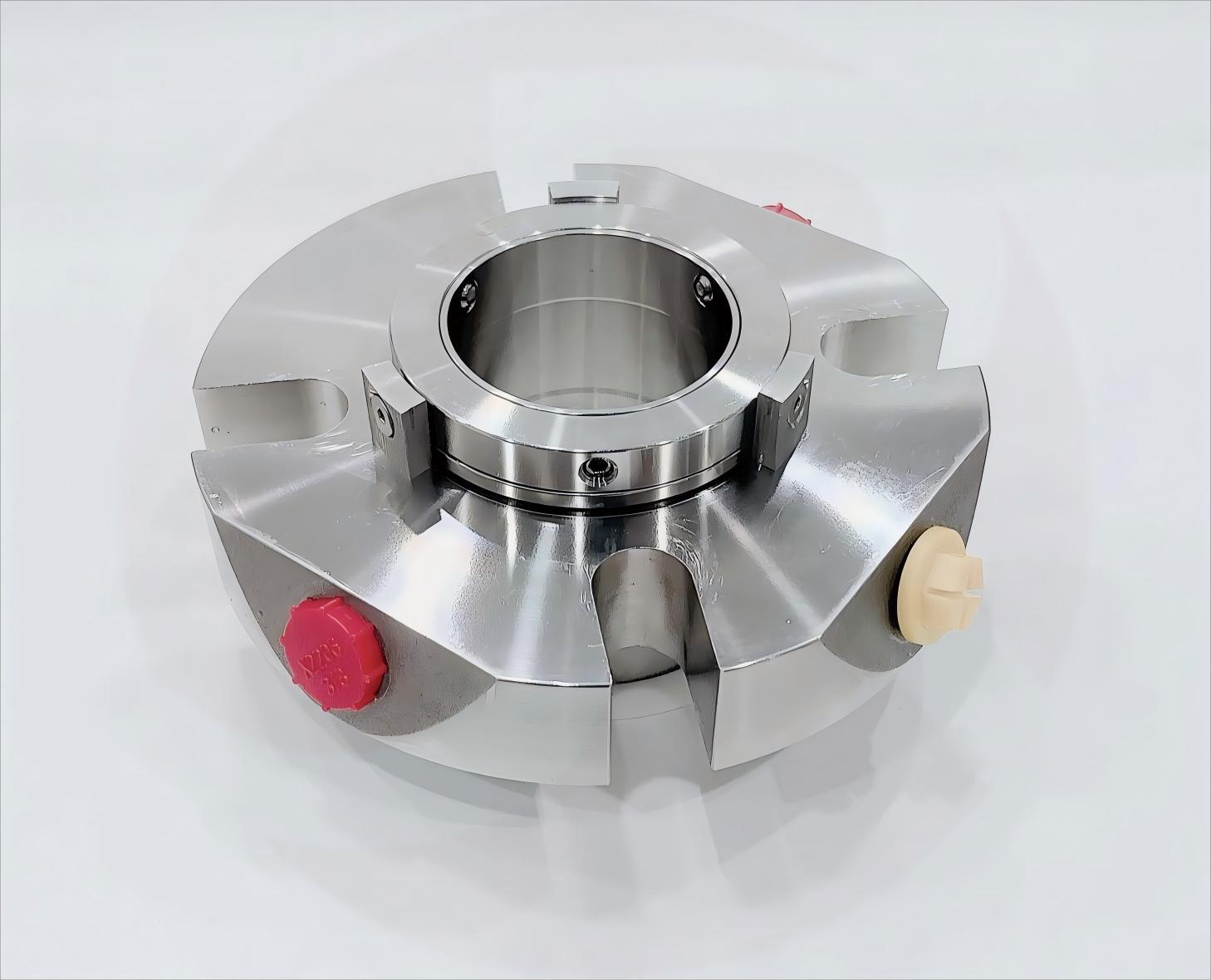

We are engaged in manufacture and installation exporting and wholesaling quality range of Industrial Seal, Single Spring Seal, Balance and Unbalance Spring Seal, External Mounted Seal, PTFE Bellow External Mounted Seal, Catridge Balance Seal, Multiple Spring Balance Seal, Dry Running Reverse Balance Seal, Agitator Double Acting Unbalance Seal, Single Conical Helical Spring, Rubber Bellow Seal, Multi Spring Seal, Metal Bellow Seal, Elastomer Bellow Seal, Conical Spring Seal, Air Condition Compressor Seal, Auto Cooling Seal, Metallic Bellow Seal,

All ranges of mechanical seals for Flygt Pumps, Grundfos Pumps, Pumps, APV Pumps, Grindes Pumps, Fristam, ABS, Alleeiler, EMU, GEA

Tunchenhagen, Godwin, Hidrostal, Hilge, Johnson, Lowara, Waukesha, Vogelsang Pumps etc.

At the meantime, we could manufacture seals according to your sample or drawing, and design as your request,Customization: Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: Where is your factory located? How can I visit there?

Answer: Our factory is located in Ningbo, China. You can fly to Ningbo or Shanghai airport directly. All our clients, from home or abroad, are warmly welcome to visit us!

Question 4: How does your factory do regarding quality control?

Answer: Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 authentication.

Question 5: How about the lead time?

Answer: Within10-20 days after getting the prepayment.

Question 6: How can we pay?

Answer: For small sample shipping cost, you can pay either by paypal or by T/T. And by T/T at sight for large amount of the order.

Question 7: If OEM available?

Answer: Yes, we provide all of our products OEM /ODM service.

Question 8: If I can buy pumps or pump parts from your company?

Answer: Yes , we also provide pumps and pump parts, such as Lobe pumps, Compound & homogeneous pumps, Homogeneous & emulsification pumps and so on

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews